MBA - Electric Steam Generator

Sussman MBA Packaged Electric Steam Generators

Small size, small capacity Sussman MBA Electric Steam Generators are perfect for industries that require efficient, high quality steam in laboratories, hospitals, computer rooms, pilot plants and for small, low-steam consuming loads.

These generators are perfect for standby operations in off seasons or when a larger boiler is shut down or unavailable. The automatic electronic controller meets all UL and ASME requirements. A main waterline pressure 10 psig greater that the operating pressure of the steam generator is required for automatic water feeding.

All MBA Steam Generators are factory tested and are ready to operate.

SUSSMAN MBA Series Features:

- Safe and easy-to-use heat source – no on-site products of combustion.

- Easy and quick to install, they require only a water feed connection and electrical hook-up.

- Steam available at the flip of a switch

- Applications include: laboratory use, steam for small tanks, reactions and distillations, autoclaves, food products, jacketed vessels for processing waxes, paraffins, glues, resins & varnishes, and wood bending.

- UL and cUL Listed

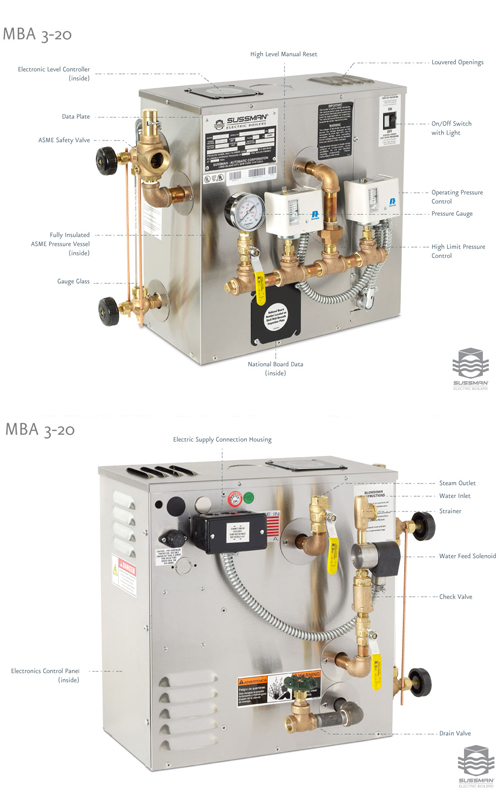

STANDARD FEATURES

- LIQUID LEVEL / LWCO CONTROLLER

The electronic controller automatically maintains proper water level, and shuts off the generator when water supply in the boiler drops below a safe operating level. - WATER LEVEL SIGHT GLASS

Allows constant observation of water level while boiler is in operation. - ON-OFF SWITCH

Complete with pilot light, for switching on the generator. - INTEGRAL ELECTRICAL CONTROL

Magnetic contactor energizes the element and is integrally mounted in the control unit. - BLOWDOWN/DRAIN VALVE

Facilitates emptying the pressure vessel during blowdown/drain sequence. - J-BOX

For motor/pump connection. - LONG LIFE HEATING ELEMENTS

Industrial grade, heavy duty stainless steel heating elements equipped with one piece resistance welded terminations for added strength and safety. - OPERATING PRESSURE CONTROL

Operates automatically to maintain steam pressure within generator. - MANUAL RESET PRESSURE CONTROL

Provides high limit pressure cut-out with manual reset. - STEAM SAFETY VALVE

ASME Code valve, automatically opens to reduce pressure should excessive steam cause pressure build-up. - STEAM PRESSURE GAUGE

Allows visual observation of steam pressure over full range. - ENERGY SAVING AND MINIMUM MAINTENANCE

Fully insulated pressure vessel minimizes heat loss and maximizes energy savings. - EASY CONTROL MAINTENANCE

All controls and components are easily accessible; Fully-louvered openings avoid component heat build-up. - RUGGED CONSTRUCTION

Performance is insured for all typical industrial applications.

MEETING CODE REQUIREMENTS

- Pressure vessel rated at 100PSIG to ASME Section I, and National Board registered.

- UL and cUL listed, built to NEC.

- All units are physically identical and have a packed shipping weight of 125 lbs.

- Units are trimmed at 100PSIG as standard. 15PSIG trim also available.

- Incoming water line pressure must be 10 PSIG greater than generator operating pressure. If not, a motor/pump must be used. Specify Sussman MBA38002A high pressure water feed motor/pump system.

- When ordering specify Model No., KW, Volts/PH and motor/pump if required.

- Water Connection is 1/4 NPT. Steam outlet is 1/2 NPT.

- IMPORTANT:

IF A BOILER IS FOR INSTALLATION OUTSIDE THE USA THE CUSTOMER/PURCHASER MUST ADVISE THE INSTALLATION LOCATION TO SUSSMAN PRIOR TO PLACING ORDER. ADDITIONAL COSTS AND/OR OTHER ACTIONS MAY BE INVOLVED IN COMPLYING WITH COUNTRY, PROVINCIAL AND/OR LOCAL JURISDICTIONAL CODE REQUIREMENTS. CUSTOMER/PURCHASER TAKES FULL RESPONSIBILITY FOR ADVISING SUSSMAN PRIOR TO THE TIME ORDER IS PLACED.