SSB - Stainless Steel Electric Steam Boiler

SSB Electric Stainless Steel Steam Boilers

- All wetted metal parts are stainless steel.

- Passivation-Pressure Vessel per QQ-P-35 Standard

- NOTE: Water with a minimum of 1 meg ohm-cm specific resistivity must be used for proper & safe boiler operation.

STAINLESS STEEL ELECTRIC BOILERS

Sussman SSB Boilers minimize contaminants because all-wetted metal parts are Stainless Steel. Whenever copper, iron or other materials cannot be tolerated in the steam and/or process, a Sussman SSB Stainless Steel Boiler is the product of choice for clean steam.

Designed for:

- Pharmaceutical, Chemical Process, Sterilization, Food Processing, Cosmetics, Autoclaves and other clean steam.

- Series 304 stainless steel pressure vessel. Series 316/316L pressure vessel available - consult factory.

- Passivation of pressure vessels and fittings

- Built to ASME Boiler and Pressure Vessel Codes Sect. I UL and cUL Listed. National Board registered.

- Tested to rigid Q.C. Inspection Procedures.

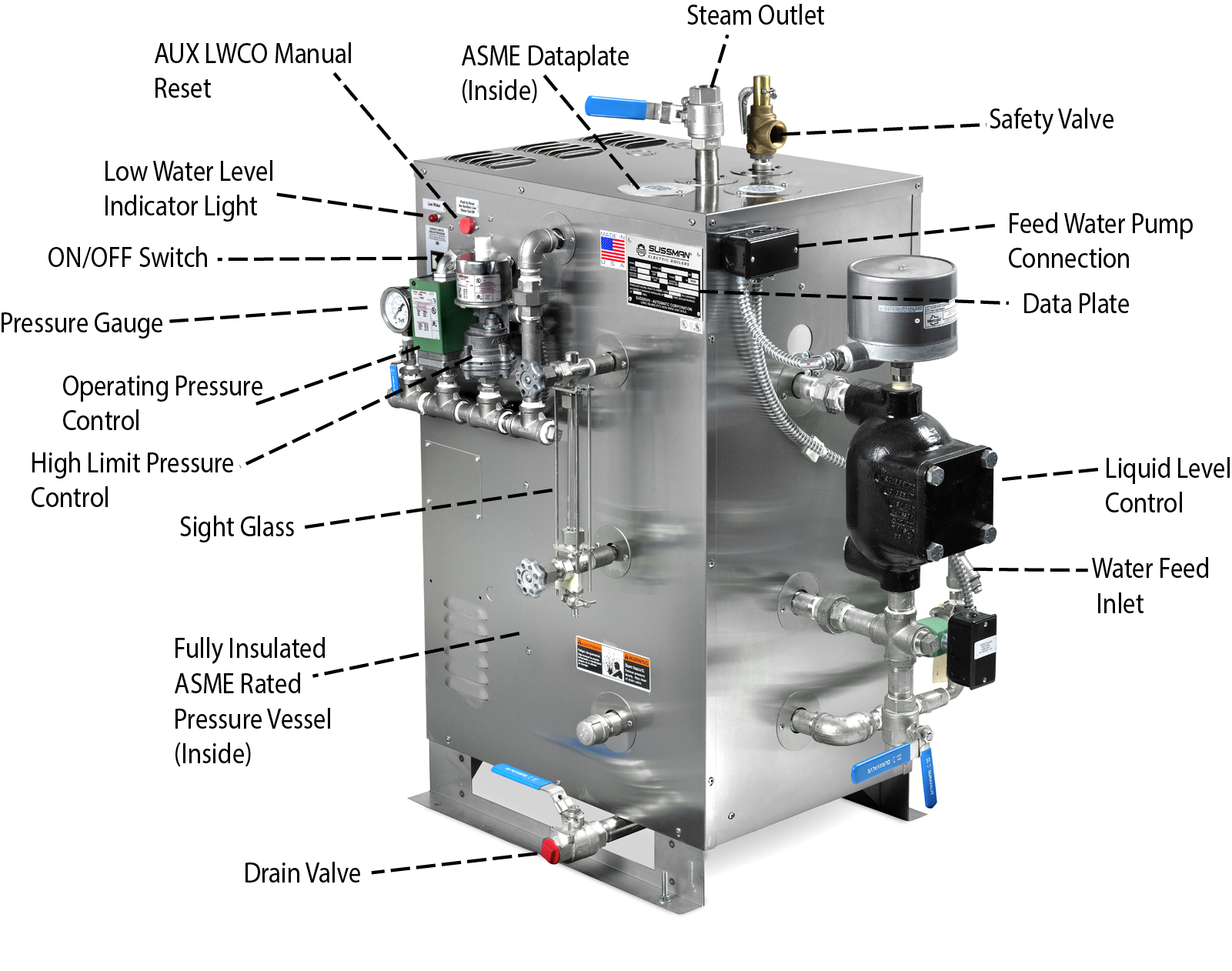

STANDARD FEATURES

- LOW WATER CUT-OFF/LEVEL CONTROL

Float type automatically maintains proper water level for safe operation and shuts off the boiler when the water supply falls below a safe level. Auxiliary low-water cut-off supplied in addition to primary control as standard - WATER LEVEL SIGHT GLASS

Permits visual observation of water level while unit is in operation. - MAIN ON-OFF SWITCH

Permits manual operation of boiler control circuit. - STEAM STOP-VALVE

Ball valve; quick closing. - PILOT LIGHT

Indicates boiler on/off condition. - INTEGRAL ELECTRICAL CONTROL

Magnetic contactors for energizing boiler elements are integrally mounted in the control unit. - BLOWDOWN/DRAIN VALVES

Permits easy blowdown and draining. - LONG LIFE HEATING ELEMENTS

Industrial Grade heavy duty 0.420 inch diameter stainless steel sheath heating elements with one piece resistance welded terminations for added life and security. - OPERATING PRESSURE CONTROL

Automatically maintains pre-set operating pressure within boiler. - RUGGED INDUSTRIAL CONSTRUCTION

- AUXILIARY LOW WATER CUTOFF

- PASSIVATION PER QQ-P-35 STANDARD

- NEMA 1 Louvered enclosure standard

- LINE PRESSURE WATER FEED

Used when incoming water pressure is at least 10 PSIG higher than operating pressure.

MEETING CODE REQUIREMENTS

- Built to ASME Section I for max 100 PSIG. Vessel National Board Registered. Code E certified

- Electrical construction conforms to NEC requirements.

- UL and cUL Listed.

- IMPORTANT:

IF A BOILER IS FOR INSTALLATION OUTSIDE THE USA THE CUSTOMER/PURCHASER MUST ADVISE THE INSTALLATION LOCATION TO SUSSMAN PRIOR TO PLACING ORDER. ADDITIONAL COSTS AND/OR OTHER ACTIONS MAY BE INVOLVED IN COMPLYING WITH COUNTRY, PROVINCIAL AND/OR LOCAL JURISDICTIONAL CODE REQUIREMENTS. CUSTOMER/PURCHASER TAKES FULL RESPONSIBILITY FOR ADVISING SUSSMAN PRIOR TO THE TIME ORDER IS PLACED.

SAFETY FEATURES

- STEAM SAFETY VALVE

ASME Code Safety Valve automatically opens to reduce pressure. - STEAM PRESSURE GAUGE

Allows visual observation of steam while unit is in operation. - MANUAL RESET PRESSURE CONTROL

Provides high limit pressure cut-off with manual reset feature.

FACTORY AVAILABLE OPTIONS

A complete complement of optional equipment for SSB and other Sussman steam boilers is described in Sussman Product sheets OES. Options covered include water feed systems, condensate returns, progressive sequencers; automatic blowdown systems, blowdown separators, transformers.